The annual global production of primary aluminum has increased from 25 million tonne in 2000 to 45 million tonne in 2012, an average growth rate of 5.2% per year. Over the same period China's annual aluminum production grew from 3 million tonne to 20 million tonne, an average growth rate of 18% per year. Everywhere you can see the application of aluminum, you can't believe that aluminum apply in aluminum projects can be so amazing.

Global production of aluminum in 2005 was 31.9 million tones. Keeping in view this excellent growth of aluminum industry in China, a symposium is being organized by the International Bauxite, Alumina & Aluminum Society (IBAAS) and China Aluminum International Engineering Co., Ltd. (CHALIECO), to show case the technological developments and also interact with the concerned engineers, technologists & scientists who made all this happen. Aluminum is the most widely used non-ferrous metal such as aluminum alloy 7020. The Symposium has been planned with the following objectives: To review the promising research and development activities aimed at improving production and productivity in the existing bauxite mines, alumina refinery and aluminum plants; To highlight the proposed greenfield activities of aluminum industry in the world with special reference to Asian countries; Latest technological developments in the field of bauxite beneficiation, alumina production, aluminum smelting, non-metallurgical bauxite and special alumina and aluminum products; Import and export potentials of bauxite alumina and aluminum in China and other Asian countries; Market and price trend of bauxite, alumina and aluminum and their products.; Non-metallurgical applications of bauxite and alumina; Latest technological developments in aluminum downstream industry; Market and price trends of aluminum downstream products.

Unlike in recent years, top consumers have a strong hand to play thanks to U.S. regulatory scrutiny into claims big banks and trade houses artificially inflated aluminum premiums by building backlogs at London Metal Exchange (LME) warehouses. The scrutiny comes alongside a proposed overhaul of warehouse practices on the LME, which has already helped knock European spot premiums down some 20 percent off a June record high near $300 a tonne.

www.aluminiumsupplier.com.cn formerly known as Guangdong Xingfa Aluminum Profile Factory was established in 1984. As one of the earliest enterprises engaged in aluminum profile in Mainland China, the Company has become a famous and large-scaled enterprise specialized in production of aluminum profiles for both architecture and industry, with its yearly capacity of 150,000 tons. The Company is the production base for aluminum alloy designated by the Ministry of Construction of China, and it was awarded "No.1 of Top-Ten National Aluminum Profile Enterprises".

In 1854, the French chemist Deville mixed up bauxite, charcoal and salt, he got NaCl AlCl3 double salt after adding the Chlorine gas and heating. Then he mixed up this double salt with an excess of sodium melt, he got aluminum. At this very time, aluminum is very precious. There is no aluminum profile supplier at that time.

In the present depressed alumina-aluminum market scenario in the world, it is necessary to evolve ways and means to improve the economics of existing plants through concerted R&D efforts. In this connection, the experience of Chinese aluminum industry in achieving this high growth rate at minimal capital and operating costs is the subject of wide interest and should be a learning curve for industry of India and other developing countries, which together have huge potential in terms of production capacities in view of their huge raw material availability and indigenous market potential for the products.

The proposal will be voted on this October, but industry players expect it to be approved given all the U.S. regulatory scrutiny, and given the LME is itself a co-defendant in private U.S. lawsuits brought on by consumers. "If anything, the risk is that the (LME rule) change may be more substantive, and there's no doubt it will have a bearing on premiums – who would want to commit with all this uncertainty hanging over the market," said Macquarie analyst Duncan Hobbs. Aluminum is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Stable aluminum is created when hydrogen fuses with magnesium either in large stars or in supernovae. Aluminum is used in many fields and you can find the information in aluminum extrusion catalogue.

The annual global production of primary aluminum has increased from 25 million tonne in 2000 to 45 million tonne in 2012, an average growth rate of 5.2% per year. Over the same period China's annual aluminum production grew from 3 million tonne to 20 million tonne, an average growth rate of 18% per year. This is in marked contrast to the corresponding figures in Western Europe, North and South America, where production has decreased. In 2012, China produced 44% of the global total, up from 11% in 2000.

www.aluminiumsupplier.com.cn formerly known as Guangdong Xingfa Aluminum Profile Factory was established in 1984. As one of the earliest enterprises engaged in aluminum profile in Mainland China, the Company has become a famous and large-scaled enterprise specialized in production of aluminum profiles for both architecture and industry, with its yearly capacity of 150,000 tons. The Company is the production base for aluminum alloy designated by the Ministry of Construction of China, and it was awarded "No.1 of Top-Ten National Aluminum Profile Enterprises".

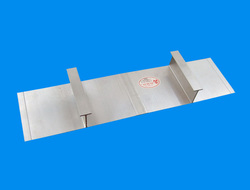

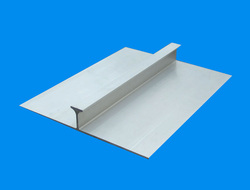

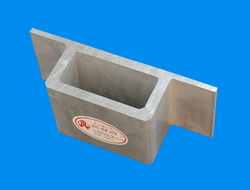

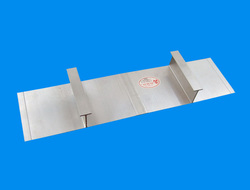

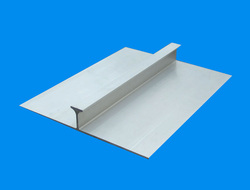

Aluminum is a great thing. You have an idea, you want something attractive, or the built-in functions, and built some practical things to last, so you choose an aluminum extrusion profiles. With shape and design, the profile can help realize your ideas. Everywhere you can see the application of aluminum, you can't believe that aluminum apply in aluminum projects can be so amazing. This article will tell you about top three questions about aluminum.

1.How can I know the hardness of aluminum profile?

Firstly, hardness has a direct relationship with the chemical composition of the alloy. Secondly, the different types of state matter a lot. From the view of the highest possible hardness, the 7 Series, 2 Series, 4 Series, 5 Series, 3 Series, 1 Series, and it is followed by reduction.

2.What is the general Use of aluminum?

Aluminum is usually alloyed – it is used as pure metal only when corrosion resistance and/or workability are more important than strength or hardness. A thin layer of aluminum can be deposited onto a flat surface by physical vapour deposition or chemical vapour deposition or other chemical means to form optical coatings and mirrors, which has been used in aluminum surface treatment. Some of the many uses for aluminum metal are in: transportation; packaging; construction; a wide range of household items, from cooking utensils to baseball bats, watches; street lighting poles, sailing ship masts, walking poles, etc. Powdered aluminum is used in paint, and in pyrotechnics such as solid rocket fuels and thermite. Aluminum can be reacted with hydrochloric acid or with sodium hydroxide to produce hydrogen gas. Some guitar models sport aluminum diamond plates on the surface of the instruments, usually either chrome or black.

3.How to choose good aluminum alloys?

Product design strength is an important factor that must be considered. Especially aluminum alloy component as structural components should be based on the pressure, select the appropriate alloy. Minimum strength aluminum and 2 and 7 Series heat-type alloy highest intensity. Hardness and strength have some positive correlation. Corrosion resistance is including resistance to chemical corrosion and electrochemical corrosion, stress corrosion and other properties. In general, a system best corrosion resistance of aluminum, 5 and performed well, followed by the 3 Series and 6 Series, 2 Series and 7 Series poor. Corrosion resistance selection should be based on the principle of the use of the occasion. High-strength alloys used in corrosive environments, you must use a variety of composite materials for corrosion protection.

aluminiumsupplier.com.cn formerly known as Guangdong Xingfa Aluminum Profile Factory was established in 1984. As one of the earliest enterprises engaged in aluminum profile in Mainland China, the Company has become a famous and large-scaled enterprise specialized in production of aluminum profiles for both architecture and industry, with its yearly capacity of 150,000 tons. The Company is the production base for aluminum alloy designated by the Ministry of Construction of China, and it was awarded "No.1 of Top-Ten National Aluminum Profile Enterprises".

China is the world's largest producer of the light metal, but also the world's largest consumer. Yet China does not have all the raw materials it needs to produce so much aluminum. Aluminum companies around the world find themselves competing with the Chinese for bauxite, alumina, even coal for the electricity needed in the aluminum smelting process.

Aluminum is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminum is the third most abundant element, and the most abundant metal, in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface. Aluminum is the most widely used non-ferrous metal such as aluminum alloy 7020. Global production of aluminum in 2005 was 31.9 million tones. AZ China predicts that domestic demand in China will continue to exhibit robust growth, and that within the horizon examined in this report demand will eventually balance out with supply. This is not a commonly-held view inside the industry. The 5-Year Outlook for China's Aluminium Industry is the most comprehensive work available on the subject.

Aluminium profile supplier are called for more ambitious EU packaging recovery policy and recycling targets by government. The EAA has always been a strong proponent of an ambitious EU packaging recovery policy and more ambitious recycling targets. However the current Packaging Waste Directive has led to a situation where different types of recovery schemes – public, private or mixed systems – have shown strengths and weaknesses in their ability to recover packaging material from different waste holder categories, being households and non-households. "If we are serious about recycling, we must considerably improve general performance level of all EPR in Europe and learn from best in class. The guidelines for Extended Producer Responsibility Schemes can help to achieve this”, said Laurent Musy, Chairman of EAA Packaging Board on the occasion of the Annual EAA Aluminum Packaging Seminar, taking place in Berlin. “Efficient collection and sorting systems are essential steps in the fight for higher recycling ambitions. The aluminum industry encourages policy makers and all actors to implement best practices and consistent approaches throughout Europe."

aluminiumsupplier.com.cn formerly known as Guangdong Xingfa Aluminum Profile Factory was established in 1984. As one of the earliest enterprises engaged in aluminum profile in Mainland China, the Company has become a famous and large-scaled enterprise specialized in production of aluminum profiles for both architecture and industry, with its yearly capacity of 150,000 tons. The Company is the production base for aluminum alloy designated by the Ministry of Construction of China, and it was awarded "No.1 of Top-Ten National Aluminum Profile Enterprises".

China is the world's largest producer of the light metal, but also the world's largest consumer. The growth in China's economy over the past decade has driven fundamental changes into its commodity supply chain. Bauxite to aluminium is a good example. The annual global production of primary aluminium has increased from 25 million tonne in 2000 to 45 million tonne in 2012, an average growth rate of 5.2% per year. Over the same period China's annual aluminium production grew from 3 million tonne to 20 million tonne, an average growth rate of 18% per year. Everywhere you can see the application of aluminum, you can't believe that aluminum apply in aluminum projects can be so amazing. This article will tell you about top three questions about aluminum. This is in marked contrast to the corresponding figures in Western Europe, North and South America, where production has decreased.

In 2012, China produced 44% of the global total, up from 11% in 2000. China has also carried out extensive R&D work to not only improve production and productivity in their existing alumina refineries and smelters but also to enable produce scores of value added products (bauxite, alumina and aluminium) and develop new technologies comparable to the best in the world at very low costs – both Capital and Operating. Aluminum is the most widely used non-ferrous metal such as aluminum alloy 7020. Global production of aluminum in 2005 was 31.9 million tones. In the present depressed alumina-aluminium market scenario in the world, it is necessary to evolve ways and means to improve the economics of existing plants through concerted R&D efforts. In this connection, the experience of Chinese aluminium industry in achieving this high growth rate at minimal capital and operating costs is the subject of wide interest and should be a learning curve for industry of India and other developing countries, which together have huge potential in terms of production capacities in view of their huge raw material availability (bauxite and coal) and indigenous market potential for

the products.

The Honourable Denis Lebel, Minister of Infrastructure, Communities and Intergovernmental Affairs and Minister of the Economic Development Agency of Canada for the Regions of Quebec, today announced that Trans-Al Network Inc. has been granted financial assistance to pursue its activities with companies operating in the aluminium sector. “Our Government supports organizations that, like Trans-Al Network, promote research, innovation, networking and market development and contribute to the diversification of the economy and job creation,” said Minister Lebel. In addition to ensuring continuation of the Trans-Al Network's activities, the funding from Canada Economic Development will also serve to support the NRC Aluminium Technology Centre's Access to Technology Project and update statistics of the Canadian Aluminium Transformation Technology Roadmap. These interventions are sure to have a positive impact on the development of this crucial industry sector.

aluminiumsupplier.com.cn formerly known as Guangdong Xingfa Aluminum Profile Factory was established in 1984. As one of the earliest enterprises engaged in aluminum profile in Mainland China, the Company has become a famous and large-scaled enterprise specialized in production of aluminum profiles for both architecture and industry, with its yearly capacity of 150,000 tons. The Company is the production base for aluminum alloy designated by the Ministry of Construction of China, and it was awarded "No.1 of Top-Ten National Aluminum Profile Enterprises".

The proper grade of aluminum alloy is significant in different jobs and applications, as the grade of aluminum helps determine its use. For example, marine grade aluminum means a specific alloy that resists corrosion, and does not deform easily. Alloys in the 5000 series as well as some 6000 are considered marine grade. Aluminum is graded by the aluminum profiles supplier for its content and heat treatment. Aluminum grades are classified into eight graded categories, from the 1000 series to the 8000 series. Generally, the higher the grade of aluminum is, the higher its quality will be. The grade of aluminum can make an influence on the materials appearance, fabrication abilities, corrosiveness, welding properties, weight as well as strength.

Before choosing the different types of aluminum alloy, people should determine the requirements that they are looking for concerning the grade of aluminum. For example, the grade of aluminum required for siding the house will be very different from the aluminum required to build parts for an aircraft.

Then people should have a good command of the knowledge of different grades of aluminum by series. Following are the introductions on different aluminum alloy series for reference: the 1000 series is resistant to corrosion, conducts electricity and heat well, and is easy to work with; the 2000 series is commonly used in aircraft, is a strong metal but less resistant to corrosion than the other grades; the 3000 series is approximately 20 percent stronger than the 1000 series, and is non-heat treatable; the 4000 series has a low melting point and is infused with silicon, and is typically used in welding wire to join other pieces of aluminum; the 5000 series has a high degree of magnesium and is a harder variant of aluminum -- this grade is popular to use for ships due to its resistance to corrosion; the 6000 series contains magnesium and silicon, giving it medium strength, good resistance to corrosion, and machinability; the 7000 series is infused with zinc, giving it a moderate to very high strength -- this series is commonly used in aircraft frames; the 8000 series displays exceptionally high strength and connectivity, and was developed specifically for aerospace applications. The right choice of the aluminum alloy is very important. For example, if you are working on a boat, then you’ll likely choose the 5000 series of aluminum. Or, if you’re making a specialized part that requires a more malleable grade of aluminum, then you’ll likely choose the 6000 series.

This article comes from:http://www.aluminiumsupplier.com.cn/News/293.htm

Aluminum is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminum is the third most abundant element, and the most abundant metal, in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface. Aluminum is the most widely used non-ferrous metal such as aluminum alloy 7020</a>. Global production of aluminum in 2005 was 31.9 million tones. It exceeded that of any other metal except iron (837.5 million tones). Forecast for 2012 is 42–45 million tones, driven by rising Chinese output.

Some of the many uses for aluminum metal are in:

1.Transportation (automobiles, aircraft, trucks, railway cars, marine vessels, bicycles, etc.) as sheet, tube, castings, etc.

2.Packaging (cans, foil, frame of etc.)

3.Construction (windows, doors, siding, building wire, etc.)

4.A wide range of household items, from cooking utensils to baseball bats, watches.

5. Outer shells of consumer electronics, also cases for equipment e.g. photographic equipment, MacBook Pro's casing

6. Electrical transmission lines for power distribution

7. Street lighting poles, sailing ship masts, walking poles, etc.

8. Substrate material of metal-core copper clad laminates used in high brightness LED lighting.

9. Aluminum can be reacted with hydrochloric acid or with sodium hydroxide to produce hydrogen gas.

10. A variety of countries, including France, Italy, Poland, Finland, Romania, Israel, and the former Yugoslavia, have issued coins struck in aluminum or aluminum-copper alloys.

Aluminum is almost always alloyed, which markedly improves its mechanical properties, especially when tempered. For example, the common aluminum foils and beverage cans are alloys of 92% to 99% aluminum. The main alloying agents are copper, zinc, magnesium, manganese, and silicon and the levels of these other metals are in the range of a few percent by weight. <a href="http://www.aluminiumsupplier.com.cn/products/Display-Rack-Other-Profile-For-Industry.htm">6061 aluminum alloy</a> is a precipitation hardening aluminum alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S," it was developed in 1935. It has good mechanical properties and exhibits good weldability. It is one of the most common alloys of aluminium for general purpose use. It is commonly available in pre-tempered grades such as 6061-O and tempered grades such as 6061-T6 (solutionized and artificially aged) and 6061-T651.

aluminiumsupplier.com.cn formerly known as Guangdong Xingfa Aluminum Profile Factory was established in 1984. As one of the earliest enterprises engaged in aluminum profile in Mainland China, the Company has become a famous and large-scaled enterprise specialized in production of aluminum profiles for both architecture and industry, with its yearly capacity of 150,000 tons. The Company is the production base for aluminum alloy designated by the Ministry of Construction of China, and it was awarded "No.1 of Top-Ten National Aluminum Profile Enterprises".

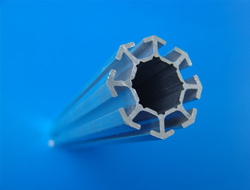

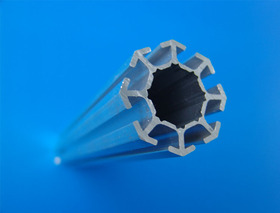

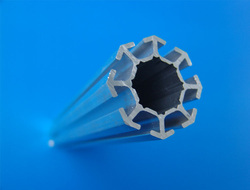

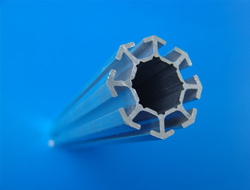

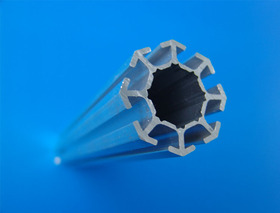

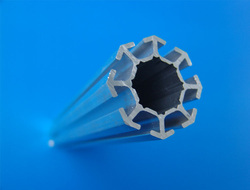

Various properties of aluminum makes it widely used in Industrial Profile Systems, the most popular application is industrial aluminum profile</a> which attaches high importance to its hardness and machinability. And what other properties does aluminum have?

<a href="http://www.aluminiumsupplier.com.cn/products/Aluminium-Alloy-6082-Marine-Sheet-with-Rib--FSW--Profile-For-Ship.htm"><img src="http://www.aluminiumsupplier.com.cn/UserFiles/image/19225405302.jpg" alt="6082 aluminum suppliers"/></a>

1. Corrosion Resistance

Aluminum has about one-third the density and stiffness of steel with only 2.7g\cm3, which in most conditions including air, water, petroleum chemistry and many chemical systems, aluminum can also be excellent in corrosion resistance, due to a thin surface layer of aluminum oxide that forms when the metal is exposed to air, effectively preventing further oxidation. And owing to this feature, aluminum is one of the few metals that retain silvery reflectance in finely powdered form, making it an important component of silver-colored paints.

2. Reflectivity

The surface of aluminum is highly reflective. Visible light, radiant heat and electric waves can be effectively reflected by aluminum. And the surface of the anodic oxidation and dark anodic oxidation can be both reflective and absorptive. Polished aluminum is excellent in reflectivity over a wide wavelength, thus it is used for many decorative purposes.

3. Thermal Conductivity and Electrical Conductivity

Aluminum is a good thermal and electrical conductor, having 59% the conductivity of copper, both thermal and electrical, while having only 30% of copper's density. Aluminum is capable of being a superconductor, with a superconducting critical temperature of 1.2 Kelvin and a critical magnetic field of about 100 gauss. The features are favorable in manufacturing heat exchanger, evaporator, heating appliances, cooking utensils, as well as the automobile cylinder head and radiator.

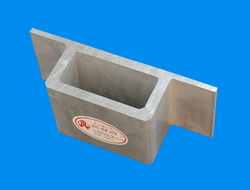

Aluminum is widely used in all kinds of buildings, such as tower, storage tank and so on. Although the cost for structural steel in infrastructure investment is low, when people are considering the structural characteristics, unique architectural engineering design, light weight and corrosion resistance, aluminum is adopted. Aluminum is almost always alloyed, which markedly improves its mechanical properties, especially when tempered. The strength and durability of aluminum alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminum a bad reputation.

The article comes from:http://www.aluminiumsupplier.com.cn/News/289.htm

Different modules have different functions, following are some modules' introductions for reference:

1050: Aluminum profile of this module is used as the extrusion, various hoses, conductive body, ship accessories, hardware items, fireworks powder in the chemical, industrial and brewing industry.

1060: this type of profile is appropriate in such occasions which have a high requirement to corrosion stability and compactibility and a low requirement to hardness. Chemical equipment is its typical application.

1100: it is used in manufacturing the components which has high corrosion stability and compactibility, such as the storage vessel for chemical products, sheet products, welding parts, heat exchanger, printing plate, name plate as well as reflective instrument.

2014: it is applied in occasions in which hardness and high intensity are required. It can be used as the heavy forging, wheel component, spacecraft part and truck frame.

2219: this module has a good weldability, high fracture toughness and a high stress corrosion cracking resistance in T8 form. The working temperature can be reached from minus 270 degrees Celsius to 300 degrees Celsius.

3003: This model is used for processing components which are required in good formability, high corrosion resistance and good weldability, such as kitchen utensils, storage devices and all kinds of pressure vessels or pipelines which transport liquid product.

5050: this type of aluminum profiles can be taken as the interior lining board of refrigerating machines, tubing, and agricultural irrigation pipe; It can also be used to manufacture thick plate, pipe, bar, special-shaped material, wire, etc.

6061: 6061 aluminum alloy requires a certain intensity, high weldability and corrosion resistance that all kinds of industrial structural properties, which can be used in manufacturing truck, tower building, vessel, trolley, furniture, machinery parts and shaped material with precision machining.

6082: this kind of aluminum is a medium strength alloy and it is high in corrosion resistance. Products manufactured in good 6082 aluminum suppliers can work in high stress such as bridges, trussed and marine.

6061 aluminum alloy is a precipitation hardening aluminum alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S," it was developed in 1935. It has good mechanical properties and exhibits good weldability. It is one of the most common alloys of aluminum for general purpose use.

6061 aluminum alloy is commonly available in pre-tempered grades such as 6061-O (annealed) and tempered grades such as 6061-T6 (solutionized and artificially aged) and 6061-T651 (solutionized, stress-relieved stretched and artificially aged).

The alloy composition of 6061 is:

Silicon minimum 0.4%, maximum 0.8% by weight

Iron no minimum, maximum 0.7%

Copper minimum 0.15%, maximum 0.40%

Manganese no minimum, maximum 0.15%

Magnesium minimum 0.8%, maximum 1.2%

Chromium minimum 0.04%, maximum 0.35%

Zinc no minimum, maximum 0.25%

Titanium no minimum, maximum 0.15%

Other elements no more than 0.05% each, 0.15% total

Remainder Aluminum (95.85%–98.56%)

Different from aluminum alloy 7020>, the mechanical properties of 6061 depend greatly on the temper, or heat treatment, of the material. Young's Modulus is 10×106 psi (69 GPa) regardless of temper. Annealed 6061 (6061-O temper) has maximum tensile strength no more than 18,000 psi (125 MPa), and maximum yield strength no more than 8,000 psi (55 MPa). The material has elongation (stretch before ultimate failure) of 25–30%. T4 temper 6061 has an ultimate tensile strength of at least 30,000 psi (207 MPa) and yield strength of at least 16,000 psi (110 MPa). It has elongation of 16%.

6061 is commonly used for the following: construction of aircraft structures, such as wings and fuselages, more commonly in homebuilt aircraft than commercial or military aircraft. 2024 alloy is somewhat stronger, but 6061 is more easily worked and remains resistant to corrosion even when the surface is abraded, which is not the case for 2024, which is usually used with a thin Alclad coating for corrosion resistance; yacht construction, including small utility boats; automotive parts, such as wheel spacers; the manufacture of aluminum cans for the packaging of foodstuffs and beverages; SCUBA tanks.

aluminiumsupplier.com.cn formerly known as Guangdong Xingfa Aluminum Profile Factory was established in 1984. As one of the earliest enterprises engaged in aluminum profile in Mainland China, the Company has become a famous and large-scaled enterprise specialized in production of aluminum profiles for both architecture and industry, with its yearly capacity of 150,000 tons. The Company is the production base for aluminum alloy designated by the Ministry of Construction of China, and it was awarded "No.1 of Top-Ten National Aluminum Profile Enterprises".

|

RSS Feed

RSS Feed